EPG is a leading manufacturing company, specializing in prefabricated (modular) data center products. We have a strong R&D team located in Shanghai, with high-end manufacturing plants in Shanghai, and Malaysia.

EPG has established a significant presence in South East Asia, Middle East, and United States regions. In China, EPG has facilities in Hong Kong, Shanghai, Beijing, Suzhou, Shenzhen, Chengdu, and Langfang.

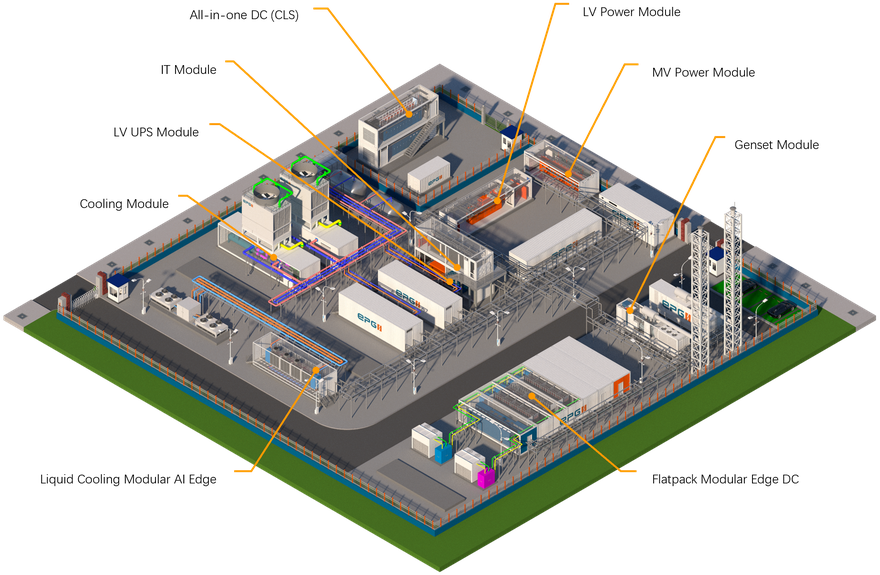

Modular DC

All-in-one DC (CLS)

All-in-one prefabricated modules provide customizable and scalable solutions for various scenarios (such as cable landing stations).

Rapid deployment

Quickly assembled on-site, reducing time required for construction and deployment

Scalability

Easy expansion and upgrades

Flexibility

Customization based on specific requirements

Cost efficiency

Deployed gradually based on demand, reducing initial investment costs.

Relocation

Can be disassembled and relocated to a different location

Liquid Cooling Modular AI Edge DC

Liquid cooling for modular AI edge DC refers to the use of liquid-based cooling solutions to manage the heat generated by GPUs.

Cooling system

indoor CDUs, secondary room manifolds and rack manifolds, outdoor pump stations, and cooling units.

Energy Efficiency

Transferring heat from GPUs directly to the liquid coolant, less energy is required for cooling.

Modular Design

The liquid cooling system is integrated into the module, providing a compact, independent solution that can be easily deployed and expanded as needed.

Reliability

Redundant pumps and cooling units minimize the risk of system failure and provide continuous cooling capacity.

Flatpack Modular Edge DC

The flatpack modular DC can be shipped quickly and customized according to user requirements with a variety of options.

Flexibility

Scalable through a variety of modules

Modular Design

Consists of LV power modules and IT modules including power systems, cooling units, busbars, cable trays, fire protection systems, and cold aisle containment.

Cooling system

The outdoor cooling source uses a fluorine refrigeration system with a magnetic levitation compressor. This fluorine refrigeration system is highly efficient, and the PUE is less than 1.3.

DC Function Modules

Genset Module

The diesel generator set is integrated with the casing, which contains an exhaust system, engine cooling system, the serviceable daily fuel tank, diesel supply system (optional), and other fire fighting equipment (optional).

The noise level of the enclosed unit is about 85DB(A) at 1 meter. The exhaust duct insulation is wrapped with stainless steel. It can withstand extreme ambient temperatures of -40℃ to 60℃, has an earthquake resistance level of 8 degrees, and supports the coastal C4 anti-corrosion level.

Belly tanks can be customized according to the oil storage time requirements (maximum fuel storage capacity 24 hours), which can replace the centralized fuel depot to save space. The belly tank corresponds to the generator set one by one to reduce single-point failures.

MV Module

The MV module adopts a modular and standardized shell, including MV power cabinets, DC panel cabinets, busway, cable tray, ELV system, fire protection, lighting, HVAC, etc.

Components are delivered pre-wired and factory inspected, making performance more predictable and minimizing risk.

The MV module can meet the reliability level of Uptime Tier 3 and above, comply with national fire protection and IT equipment room construction standards, and the interior of the container is sprayed with reflective heat insulation coating and waterproof treatment.

LV Power Module

The LV power module is divided into two compartments, one for the transformer and the other for the LV system.

The LV system integrates LV switchgear, SVG, UPS, busbar, cable tray, air conditioner, ELV system, fire protection system, lighting, etc., and is tested in the factory, which greatly improves the assembly efficiency of on-site construction, makes its performance more predictable, and minimizes risks.

LV UPS Module

The LV UPS module can separate two physical spaces for A/B LV systems.

This module integrates power panels, UPS and batteries, busbars, cable trays, ELV systems, fire protection systems, lighting, air conditioning, etc. It is fully prefabricated in the factory and undergoes UPS performance tests, burn-in tests, waterproof tests, and hoisting tests, greatly improving on-site construction efficiency.

IT Module

The IT module integrates IT racks, cooling units, fire protection systems, ELV systems, lighting, etc. into one container.

The IT module supports fast and flexible deployment and can be expanded to a multi-layered data center or a flatpack scenario to meet the needs of small data centers. It can also support multi-layer stacking for large data centers, which is suitable for phased construction and land use scale.

In terms of cooling solutions, it is also compatible with chilled water systems, fluorine refrigeration systems with magnetic levitation compressors, air-cooled DX systems, and liquid cooling systems. The indoor cooling units can be selected from fan wall units, room air conditioners, in-row air conditioning units, and cold plate liquid cooling systems.

Prefabricated chiller plant

The prefabricated chiller plant serves as a cold source to provide chilled water for data centers, including chiller modules, hydraulic pipeline modules, cooling towers, buffer tanks, etc.

The chiller module includes a chiller, water pumps, sand filter, water treatment system, cable trays, fire protection, lighting, HVAC, as well as a BA system and BMS system.

All the above equipment and internal pipelines and valves are integrated and installed inside the module, and various tests are carried out in the factory, which can greatly reduce the difficulty of on-site operations and shorten the construction period.