Demand has already started to exceed supply of Nvidia’s upcoming Blackwell-series AI chips, leaving companies involved in the manufacturing process scrambling to increase capacity to meet order requests.

According to a report from Taiwanese news outlet United Daily News (UDN), Nvidia has increased its production volume with TSMC in response to a doubling of orders in the fourth quarter, which in turn has had a knock-on effect on back-end packing and testing plants.

In order to meet demand, King Yuan Electronics Co (KYEC), one of the world's largest testing and packaging services firms, has “mobilized internally” to try to stop itself from becoming overwhelmed with orders.

To compound the issue, according to the news outlet, the testing process for the Blackwell-series is significantly longer than that of the previous Hopper-series. This involves a final packing test (FT test), a burn-in test, an additional FT test, and finally a System Level Test (SLT).

The increased power consumption of the Blackwell chips has also reportedly increased the difficulty, with the testing companies having had to increase the capacity of its burn-in test chambers from 600W to 1kW.

KYEC is taking advanced chip testing orders from the company, with ASE Technology taking advanced packaging & testing orders to help reduce the burden. Despite the challenges borne out of the increasing demand, UDN reported that both ASE and KYEC have seen an improvement in their profit performance as a result.

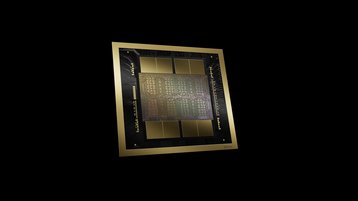

First unveiled in March 2024, the Blackwell GPU family is set to be available later this year.

Manufactured using a custom-built, two-reticle limit 4NP TSMC process with GPU dies connected by 10TBps chip-to-chip link into a single, unified GPU; Blackwell chips have 208 billion transistors, an increase on the 80bn in the Hopper series. It is twice the size of the Hopper.

The GPU also includes a second-generation transformer engine and new 4-bit floating point AI inference capabilities, and features a new dedicated engine for reliability, availability, and serviceability, with AI-based preventative maintenance to run diagnostics and forecast reliability issues.

During his keynote speech at Computex earlier this month, Nvidia CEO Jensen Huang announced that the company’s upcoming semiconductor roadmap will now see a new product family launched every year, with Blackwell’s successor, dubbed Rubin, set to be available in 2026.