Social media firm Meta is attempting to redesign fiber signal amplification sites.

In the same way subsea cable systems have repeaters every ~100km to amplify signals being sent between locations, in-line amplifier (ILA) sites amplify signals sent along terrestrial fiber.

As fiber was rolled out along roads, railways, and pipelines from the late 1970s onwards, real estate to house optical signal repeaters was developed in parallel in large numbers across the US. These small sites are sometimes called ILA/repeater shelters.

The social media firm has been looking to update how these fiber shed sites are built and deployed, and recently detailed its ideas and ambitions.

“Over the past year, Meta has been on a journey to reimagine fiber optic in-line amplifier (ILA) sites,” the company said in a recent blog. “Meta is excited to introduce new ideas and concepts to help modernize the ILAs for tomorrow.”

Early ILA sites were spaced 18 to 25 miles (30 to 40 km) apart – rising to 50 to 60 miles (80 to 100 km) amid technology improvements, which has largely remained the case today.

Early ILAs were reportedly roughly modeled on Bell Telephone central offices, creating a shrunken-down version. Meta notes these designs include concrete shells (or stick framed construction on a steel I-beam base) placed atop concrete foundations; wall-mounted HVAC units; -48V power distribution; lead-acid batteries; diesel backup generators etc, surrounded by chain link fences.

“Buildings were constructed in a central location with [the] inside plant fitted into the shell before shipment to the site (via specialized motor carrier) and placed with a heavy-load crane,” Meta said. “However, unlike the remarkable (and ongoing) advancements in fiber and optronics (e.g., CWDM to DWDM to Coherent DWDM), ILA sites themselves have received little attention.”

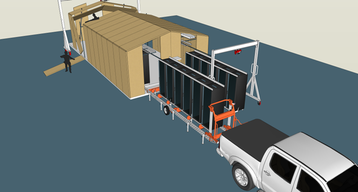

Meta is now looking to redesign ILAs to meet its new requirements: the building and inside plant must be deployed in three to four days; reducing the need for heavy equipment such as heavy-lift cranes; reducing the amount of concrete required; and reducing PUE to below 1.5 – described as “nowhere near” Meta’s average 1.09 data center PUE, but an “achievable and significant improvement.”

“Working with global engineering consultancy AECOM, we’ve organized the problem and our engineering efforts into several categories: different building systems and foundations; a new inside plant installation method; alternative ballistics protection; introducing more efficient cooling; and modernizing backup power systems,” the company noted.

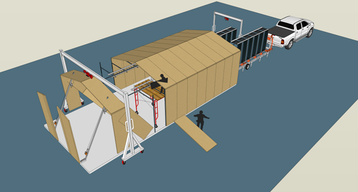

On the build side, the company has been focused on lightweight designs that can be flat-packed and unloaded quickly. Meta has been looking at buildings composed of fiberglass-reinforced polymer (FRP, aka glass-reinforced polymer or GRP) wall and roof panels that are light enough for two people to handle.

For the foundations, Meta is looking to utilize low- or no-concrete foundation designs where geology permits easier deployment into both greenfield and brownfield sites. The use of lighter buildings has made such options more viable.

Inside, the social media firm is looking to develop a pre-assembled six-rack system that be rolled into the ILA buildings. The company suggests each building could consist of 24 racks.

As ILA power requirements have moved from 600-800W per rack into the 2-4kW range, Meta is looking to improve the PUE of these sites through the deployment of a loop thermosyphon system coupled with a compressor, as well as deploying liquid cooling. But challenges remain.

“The project hasn’t made a final selection yet as these technologies will make our goal of “no cranes” difficult to achieve,” Meta said, “but we believe we have line-of-sight to a solution.”

To replace the backup diesel generators, the company is exploring H2 fuel cells, capacitors, and other solutions.

“We believe an H2 fuel cell combined with a small NaNiCl molten salt battery system (to handle site load for a few minutes while the fuel cell spins up and takes load) is an attractive, low maintenance solution.”

As well as building new ILAs, Meta said it was exploring retrofitting the internals of existing sites.

Following the completion of the research and design phase, Meta has started engaging fiber optic operators in North America and Europe to gather early feedback. This will be expanded to operators in Latin America, Africa, the Middle East, and Asia in the coming months.

A prototype site showcasing some of the best ideas from this project is expected to be developed later this year. Learnings will be shared,

“We plan to create and broadly share blueprints, bills of material, and analyses that show our path and help seed operators’ own research, engineering, and technical real estate product development,” the company said.

Unified Building Group says it has completed ILA projects in 33 states for companies including Facebook, Zayo, Google, CenturyLink, and Level 3, as well as Tesla and SpaceX.