As the IT landscape evolves, cooling systems must adapt to meet the demands of emerging technologies like AI and increasingly complex server infrastructures. In a recent discussion with DCD, Vertiv’s cooling experts shared insights on the challenges and opportunities in cooling architectures, emphasizing the need for flexible, hybrid solutions.

Challenges and opportunities

One of the key obstacles to meeting IT requirements today lies in the uncertainty of emerging technologies, particularly the integration of new GPU servers for AI. As technology rapidly evolves, data center operators must be prepared for the increasing rack density, server power demands, and heat dissipation technologies required. Do they have the right equipment? Will their infrastructure withstand the next technology refresh?

Adding to the complexity, advancements in GPU technology generate more heat, requiring more effective cooling solutions. At the same time, regulatory changes for sustainability focus on adopting low global warming potential (GWP) refrigerants, further reshaping cooling strategies.

Ben Smith, Vertiv’s vice president of DX (direct expansion) thermal systems, opens the discussion by highlighting the growing importance of liquid cooling solutions, which are being deployed in various ways to manage rising heat output effectively:

“Liquid cooling is taking off, with CDUs being integrated in different ways – sometimes in the rack, sometimes in the room, sometimes in the row. At the same time, there was an expectation that air cooling would decrease over time, but it's actually increasing due to higher density.”

In liquid cooling, water is directly applied rather than air, allowing the heat from the chip to be absorbed into the water, causing its temperature to rise proportionally. This requires a significantly different control routine to that of air cooling, adding complexity for customers looking to upgrade their data centers to accommodate AI applications.

Drawing from extensive engineering experience, George Hannah, senior director of global chilled water systems, explains:

“With lower thermal inertia, the system reacts faster, at elevated temperatures, using different control routines, and a new thermal chain from the chip to the atmosphere. All of that changes temperatures, flow rates, and response speeds, and our products have to change to adapt accordingly.”

As liquid cooling systems transfer more heat into a water circuit at higher temperatures, large-scale facilities face a choice: traditional heat rejection, or the opportunity to recover and repurpose heat for applications like local community heating, farming, or even carbon capture. In response, Vertiv is actively integrating heat recovery into its products and developing dedicated solutions to maximize its potential. Hannah shares a local example:

“In Manchester, a data center has partnered with the local council to supply excess heat to a recovery system, providing heating for a new residential community and commercial area. It’s a brilliant example of sustainable innovation.”

This shift in thinking has had a profound impact on the industry’s approach to cooling and sustainability:

“For many years, liquid cooling threatened to be something that would transform the industry in a certain way. In reality, it certainly has transformed the industry, but not quite in the way everybody predicted,” Hannah relays.

Fail to prepare, prepare to fail

The rapid advancements in chip manufacturing, AI, and server architectures make it difficult for businesses to predict their future IT needs with certainty. So, what happens if a customer fails to plan for those future requirements?

With Vertiv’s approach, there is always a backup plan in place, so if the initial plan doesn’t fully meet the evolving demands of the customer, there’s flexibility to adapt. However, this is no simple task, as the pace of industry developments requires these backup plans to evolve just as quickly. Andrea Moscheni, Vertiv’s product manager for global chilled water systems, explains how Vertiv prepares for the future needs of its customers, emphasizing the importance of anticipating not just immediate needs but also the flexibility to address unforeseen challenges and opportunities:

“We have established partnerships with Nvidia and other chip manufacturers in advance because that's where the evolution of AI began. We co-develop solutions with partners like that to design the future of the AI factory, and we’re designing innovative solutions together with our customers to solve challenges that didn’t exist in the past.”

Smith supports this approach by noting: “Starting a few years ago, we’ve seen chip vendors dedicating more time to the infrastructure challenges of the data center, not just focusing on the server and fan power. This shift is filtering through to the server space, and companies like Vertiv are now involved right from the chip, helping to find the best solutions that start with the chip’s power.”

Smith adds that Vertiv’s broad portfolio of solutions enables the company to collaborate with partners and customers in an agnostic way, tailoring solutions to meet specific customer needs. He explains that rather than opting for a single-product approach, customers generally seek hybrid solutions, often combining liquid cooling with air-based systems, such as chilled water (CW) and direct expansion (DX.) These solutions can be implemented within the same footprint or distributed across multiple units, depending on the data center’s design and cooling requirements.

Hannah reflects on how this shift has influenced customer behavior, noting a pause in the rush to implement outdated architectural designs:

“To avoid designing themselves into a corner, customers are rethinking their facilities. They’re taking time to understand what it means to have a high-density facility with liquid cooling, and they’ve re-architected their systems accordingly.” He adds:

“Through our partnerships, we’re offering customers technologies and solutions that provide a much broader range of performance. While they’re still figuring out the full potential of liquid cooling, they know they need to adapt their architecture to accommodate it.”

Designing for a liquid future

With the future of high-density data center design increasingly centered on hybrid architectures that combine both liquid and air heat removal, the next challenge is determining how to manage these systems effectively. Hannah highlights the complexity of this task:

“You don't quite know how much will go to air and how much will go to liquid. So the solution must be flexible enough to handle both.”

Alessandro Zerbetto, product manager for Vertiv DX Systems, underscores the importance of flexibility in delivering these solutions: “We have customers deploying for low- or mid-density applications today, but we must stay ahead by offering flexible solutions that can scale with the growth and changing configurations of data centers.”

The Vertiv team, across departments, agrees on one thing: Future data center deployments need to be much larger, rapidly deployable, and standardized compared to the past.

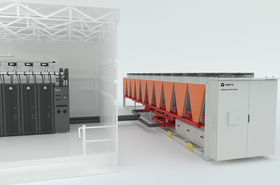

To illustrate how this works in practice, Zerbetto introduces the Vertiv CoolPhase Flex, a versatile ‘future-ready’ unit that can switch between air and liquid cooling. He explains:

“New data centers typically start with all air-cooling units, as they are initially designed to support low-density racks. As demand for AI and high-density workloads grows, these cooling units can be quickly and easily converted to supply liquid cooling without the need for replacement. This allows data centers to adapt, maintaining a mix of air- and liquid-cooled units, tailored exactly to the data center's needs.”

For example, areas with low-density racks might still require air cooling, while areas growing in density over time – from low to mid to high – will need liquid cooling. In such cases, units can quickly be converted to provide liquid cooling to those parts of the facility.

The Vertiv CoolPhase Flex was developed in collaboration with Compass Datacenters, addressing the very challenges discussed: uncertainty and how to manage the changes ahead. Smith highlights that by working closely with Compass Datacenters, Vertiv deployed a system capable of adapting to evolving technologies over the next decade:

“The system can adapt, shifting the air-to-liquid ratio as needed – potentially reaching a 50/50 balance or reversing entirely. The speed to market allows for greater flexibility in the architecture, and even future innovations, such as single units capable of handling both air and liquid cooling for smaller applications.”

A key trend in data center cooling is the shift toward higher operating temperatures. This is largely due to the rapid evolution of next-generation chip technology to cope with high-performance computing, causing the water working temperature threshold to increase. While cooling remains essential to maintain IT equipment reliability, higher operating temperatures offer additional benefits, such as reduced energy consumption and greater potential for heat recovery. For Hannah, this makes hybrid data centers with chilled water systems an ideal choice, due to their ability to seamlessly integrate with these diverse cooling strategies:

“A good example is the Vertiv CoolLoop Trim Cooler, one of Vertiv’s new solutions that meets this need by offering a platform capable of adapting to a wide range of supply and return water temperatures – up to 40°C (supply) and 50°C (return) – while achieving 70 percent greater efficiency at high densification.”

The crux of hybrid architecture

For years, technology in the data center industry has prioritized cost, but today’s focus has expanded to include environmental impact, density, and deployment speed. Hannah emphasizes that customers are now seeking flexible, high-performance solutions rather than simply opting for the cheapest option – especially in the competitive race for AI power. This is where hybrid architecture plays a crucial role.

According to Smith, the ideal hybrid solution depends on space availability and the design of the building. For larger sites, the Vertiv CoolPhase Flex works well, while smaller, more compact spaces may require split or combined DX systems. The key is adaptability –making sure solutions align with both future needs and the physical constraints of the building.

Hannah adds: “Hybridization addresses these needs by combining efficiency and adaptability. It’s similar to hybrid cars – hybridization is now a natural progression, solving more than just economic challenges using combined technologies. Whether you’re deploying DX or CW systems, we are well-equipped to address the demands of densification. By integrating with liquid cooling technologies directly, our technologies provide the thermal performance needed for high-density environments. Additionally, their scalability allows them to adapt as workloads grow, maintaining efficiency and reliability.” Moscheni further explains:

“A key advantage Vertiv provides is advanced control systems, which simplify thermal management when multiple technologies are combined. This allows customers to focus on their servers and equipment while maintaining efficient cooling solutions.”

By embracing collaboration and hybrid solutions, smarter architectures integrate existing technologies and provide flexibility for future cooling needs – whether liquid or air systems, or a mix of both. This approach allows data centers to remain functional for years without requiring complete overhauls as technology evolves.

Ready to embrace the future of cooling? Learn more here.

More from Vertiv

-

Sponsored Vertiv and Tecogen forge global partnership to enhance cooling solutions for power-constrained data centers

Vertiv to offer Tecogen’s natural gas-powered chiller to customers leveraging alternative energy sources to reduce grid reliance

-

Podcast Episode Episode 71 - AI in Australia with Ben Crowe, Vertiv

-

Vertiv launches new trim cooler with up to 3MW of cooling capacity

Cooler reportedly avoids F-gases